Key Takeaways

- Insulin is a two-chain peptide with specific disulfide links.

- Zinc-driven hexamers store insulin; monomers perform receptor binding.

- Modern production uses recombinant DNA in bacteria or yeast.

- Molecular weight guides assays, formulation, and unit conversions.

Understanding insulin chemical structure helps connect lab design with real-world therapy. You will see how its chains, bonds, and manufacturing steps shape performance and safety.

Understanding Insulin: Molecule, Function, and Signaling

Insulin is a polypeptide hormone (protein signal) that regulates glucose entry into tissues. Clinically, it lowers circulating glucose by promoting uptake in muscle and fat. It also suppresses hepatic glucose output and modulates lipid metabolism. These effects stabilize energy balance across meals and fasting.

At a cellular level, insulin initiates a cascade after receptor activation. Membrane transporters shift, enzymes switch states, and gene programs adjust metabolism. These coordinated responses help maintain euglycemia across varying conditions. For a concise role overview, see Main Role Of Insulin for context on physiological actions.

For foundational background, this NCBI Endotext overview explains structure–function relationships across experiments and species with clinically relevant detail.

Insulin Chemical Structure: Chains and Bonds

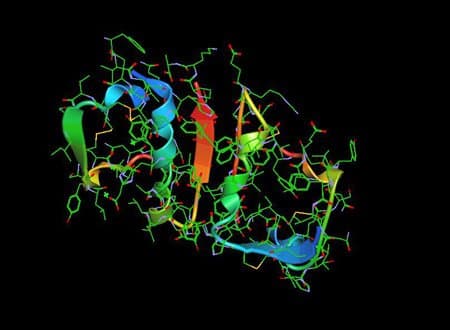

Human insulin contains two peptide chains: A (21 amino acids) and B (30 amino acids). Two interchain disulfide bonds link A7–B7 and A20–B19. A third intrachain disulfide bond stabilizes the A chain (A6–A11). This compact design enables correct receptor binding and rapid conformational shifts.

In solution, insulin self-associates into dimers and zinc-coordinated hexamers. The hexameric storage form improves stability in vials and pens. At the receptor, however, the active species is the monomer. Formulation chemistry therefore balances storage stability with timely monomer release. For structural comparisons across products, see Human Insulin vs Analog Insulin for contrasts between backbones and modifications.

A detailed, curated protein record further describes sequence variants and domains; see the UniProt entry for human insulin for sequence and annotations.

From Source to Synthesis: Modern Production

Today, most manufacturing relies on recombinant DNA technology in microbes. Insulin genes are inserted into microbial hosts to express precursor polypeptides. Depending on the platform, producers may use Escherichia coli or certain yeasts. Each route optimizes yield, folding quality, and downstream purification.

Historically, semisynthetic approaches converted porcine molecules to human sequence. Those methods have largely been replaced by higher-capacity microbial systems. Modern facilities emphasize traceability, viral safety steps, and validated analytics. Within this landscape, insulin production by bacteria highlights scalable, cost-conscious workflows with robust controls.

For historical context, the FDA documents the first recombinant drug approval, human insulin, in 1982 as a key biotech milestone. For deeper biotech reading, explore Research articles on our site for evolving methods and assays.

Molecular Weight, Units, and Practical Metrics

The molecular weight of insulin is approximately 5,808 daltons for the human monomer. In kilodaltons, this equals about 5.8 kDa, often rounded in texts. Dimer and hexamer assemblies increase the apparent mass in biophysical assays. Zinc-bound hexamers approach roughly 36 kDa before accounting for solvent interactions.

These numbers matter for chromatography, diffusion modeling, and unit conversions. Assay calibration often references molar amounts instead of international units. Researchers may convert to grams per mole for kinetic comparisons. Clinicians may find dose discussions in our Insulin Dosage Chart for context on unit conventions and practical ranges.

Human vs. Analog: Structure–Function Tweaks

Human-sequence products match endogenous protein and provide a baseline profile. Analogs modify residues or add side chains to alter absorption and duration. Rapid-acting designs adjust the B-chain interface to reduce self-association. Ultra-long designs often attach lipid moieties that promote depot effects.

These changes tune onset, peak, and tail without altering core mechanisms. In practice, selection depends on goals like meal coverage or basal stability. To see product-level examples, review Basaglar Cartridge for a long-acting case study, and Once Weekly Insulin for emerging dosing models in development. Within this field, insulin analogs reflect sequence engineering guided by pharmacokinetics.

Historical Sources and Ethics

Before recombinant techniques, manufacturers purified insulin from animal pancreas. Porcine and bovine sources supported decades of care, with careful refinement. With modern biosynthesis, animal harvesting is largely unnecessary for humans. This shift improved purity, allergen control, and supply consistency worldwide.

People sometimes ask, is insulin made from pigs in current practice? Human therapy today predominantly relies on recombinant platforms rather than animal extraction. Veterinary medicine can differ by species and formulation, as with ProZinc Vial used in feline diabetes for species-specific needs. For storage practices relevant to households, see Pet Insulin Storage for cold-chain and handling parallels.

Biological Action: Binding and Downstream Effects

Insulin first binds its dimeric receptor, a transmembrane tyrosine kinase. Ligand engagement triggers autophosphorylation and adaptor recruitment. Downstream pathways include PI3K–AKT for metabolic actions and MAPK for growth signals. Tissue context and dose shape the net outcome across these cascades.

In research and clinical texts, insulin receptors define the entry point for signaling. From there, transporters like GLUT4 translocate in skeletal muscle and fat. Hepatic enzymes alter gluconeogenesis and glycogen synthesis. For pathway effects on carbohydrates, see Insulin And Glucose for a targeted explanation of handling and flux.

Production Workflow at a Glance

Manufacturers execute a defined series of upstream and downstream steps. Upstream, cell banks and seed trains prepare the production host. Bioreactors run fed-batch or perfusion modes to maximize expression. Inclusion bodies or soluble expression dictate later refolding strategies.

Downstream, producers harvest, lyse, and clarify before capture chromatography. Enzymatic cleavage yields the proinsulin or split chains. Correct folding and disulfide pairing occur under controlled redox conditions. High-performance chromatography, crystallization, and filtration deliver final purity and potency.

Documentation often summarizes the steps of human insulin production in a validated map. Industrial guides may show a human insulin production flow chart to highlight checkpoints. Formulation then adds excipients, zinc, and buffers to stabilize storage. Co-formulations, such as Soliqua SoloStar Pens or Xultophy Prefilled Pen, illustrate broader formulation strategies pairing hormones for clinical aims.

Tip: Terminology varies by facility; consult site-specific batch records for exact step names.

Clinical Relevance: Manufacturing for Type 1 Needs

Reliable manufacturing underpins safe, consistent therapy for patients. Quality systems and regulatory oversight help keep variability within tight limits. Batch analytics confirm identity, purity, potency, and aggregate levels. These controls support predictable pharmacology at the patient level.

Regarding patient questions, how is insulin made for type 1 diabetes is fundamentally the same as for all indications. The difference lies in formulation choices and delivery methods, not the protein itself. For background on treatment approaches, browse Diabetes Articles for broader disease education. As new options emerge, see Human Insulin vs Analog Insulin for structure-guided differences that may influence clinical selection.

Recap

Insulin’s two-chain design, disulfide bonds, and zinc-driven assemblies enable stability and action. Recombinant platforms scaled production while improving purity and traceability. Molecular weight metrics link laboratory assays with formulation practice. Together, these elements explain how structure and production shape clinical performance.

For storage thresholds and practical use cases, our related guides provide context across research and therapy. Continue exploring to connect molecular design with day-to-day management and future innovations.

Note: This content is for informational purposes only and is not a substitute for professional medical advice.